|

Ceronics

Inc. is a manufacturer of metallic coatings that are fired

on ceramic bodies. Our products range from molybdenum, tungsten and

silver for electronics, to gold for decorative applications.

Since 1959, Ceronics, Inc. has been

supplying a worldwide clientele who demand custom pastes that fit their

unique application and firing guidelines. We can supply you with any size

batch to meet your job requirements. Ceronics, Inc. can also make into

paste form various types of metallic powder that is supplied to us.

We are

manufacturers of ...

Molybdenum-Manganese

Conductor Paste

Our Moly/Mang metalizing compositions

are screen printable, thick film conductor paste used as a surface

conductor on aluminum nitride, silicon nitride, beryllium oxide, and

alumina substrate material. These

compositions are typically fired at high temperature in a reducing

atmosphere.

| TECHNICAL PROPERTIES

|

- Metalizing

particle size less than 2 microns

- Screened deposition thickness as fired approximately .0005 thick

- Viscosity

- Customized to meet your criteria

- Shelf

life of six months minimum

|

| TYPICAL DRYING CYCLE

|

- One

hour ambient temperature

- Thirty

minutes at 150° F

- Thirty

minutes at 450° F

- Parts

should be kept hot until placed in metalizing furnace

- Cycle

times can be reduced if drying lamps or other similar

semi-automated cycles are used.

|

| TYPICAL FIRING CYCLE |

- Atmosphere:

H Wet (75° Dew Point)

- Temperature:

1300°C to 1580°C (depending on formulation)

- Time:

Thirty to forty five minutes at temperature

- Slow

preheat and cool recommended.

|

M-20

Tungsten Conductor Paste

Our Tungsten metalizing compositions are screen

printable, thick film conductor paste used for buried electrode layers in

multiplayer ceramics. These

compositions are typically fired at high temperature in a reducing

atmosphere after application to green ceramic tape.

| TECHNICAL PROPERTIES

|

- Metalizing

particle size less than 2 microns

- Screened deposition thickness as fired approximately .0005 thick

- Viscosity

- Customized to meet your criteria

- Shelf

life of six months minimum

|

| TYPICAL DRYING CYCLE

|

- One

hour ambient temperature

- Thirty

minutes at 150° F

- Thirty

minutes at 450° F

- Parts

should be kept hot until placed in metalizing furnace

- Cycle

times can be reduced if drying lamps or other similar

semi-automated cycles are used.

|

| TYPICAL FIRING CYCLE |

- Atmosphere:

H Wet (75° Dew Point)

- Temperature:

1300°C to 1700°C (depending on formulation)

- Time:

Thirty to forty five minutes at temperature

- Slow

preheat and cool recommended.

|

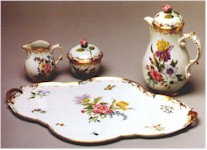

24-Karat

Burnishing Gold

Gold for china & porcelain

decorating is also available. These products are available in various gold

percentages.

|

|

|

|

|

Pictured is Ceronics gold on fine china

custom decorated by our customer, Daisy Muff of Overland Park, Kansas.

|

|

Ceronics, Inc.

also

manufactures Nickel, Nickelous Oxide, Silver, and Silver/Palladium

products to meet your specifications. We manufacture these products at

high temperatures by metalizing compositions for screening, brushing,

dipping and spraying.

Specializing

in custom mixes to meet YOUR specifications.

|

|

|

P.O.

Box 75 · 5 Dock Street

Matawan, NJ 07747

Phone: (732) 566-5600

·

Fax:

(732) 566-9317

email: ceronics@verizon.net |

|

|